-

What Is Digital Printing?

In short, DuraTech Industries’ digital printing is similar to an industrial version of an at-home printer. However, our “at-home” printer is built for industrial grade performance, meaning it is specifically designed to produce a greater quality and quantity than your standard desktop printer. We use this technology to deliver high-quality finishes to your products that… June 25, 2025

-

DuraTech’s IME: Dependability Through 4 Quality Tests

“Just how robust is your IME process?”We hear this question with increasing frequency. It’s a valid query. In-mold electronics (IME) technology is growing rapidly due to the attributes it offers engineers in designing 3D, smooth, decorative and easily cleaned surfaces with integrated capacitive touch, lighting, haptic feedback and antennas. IME also offers advantages in the reduction of… May 21, 2024

-

Enhance Your Home with Capacitive Touch Technology

What is capacitive touch?Capacitive touch, commonly known as cap touch, is a feature of in-mold structural electronics (IMSE) that is used in touchscreens and other touch-sensitive surfaces. At its core, capacitive touch relies on the electrical properties of the human body to detect and respond to a user’s touch. This technology is gaining immense popularity, particularly among… March 7, 2024

-

What You Need to Make Your Smart Products Attract Attention

In the ever-evolving environment of technology and innovation, those in the functional electronics industry are confronted with the need to not only keep pace but to stand out among competition. As we dive into the world of in-mold structural electronics (IMSE®), also referred to as in-mold electronics (IME), it is clear that improving the customer experience… February 20, 2024

-

Printed Heaters: Innovative Heating Solutions

Printed heaters, born from printed electronics (PE), represent a revolutionary solution to age-old heating challenges. They offer durability, customization and space-savings, addressing the challenges experienced in traditional heating methods. This innovation is transforming heating solutions across various industries, promising a future where flexibility and efficiency join to meet the world’s heating needs. What are printed… October 23, 2023

-

DuraTech is Helping to Shape the New Frontier in Flexible Electronics

Interest and demand for flexible electronics continues to skyrocket among industries and consumers alike. From stretchable electronics for medical sensors to consumer electronic wearables and heated apparel, the flexible electronics market is expected to surpass $61 billion by 2030, according to some reports. While the technology exists to produce products like heated garments, significant challenges… September 5, 2023

-

Empowering Local Change: DuraTech’s Dedicated Volunteers Making a Difference

At DuraTech, we firmly believe that empowering our Team Members to volunteer not only benefits the communities they serve but also enriches their personal and professional lives. Volunteering can become a journey of self-discovery, skill-building, and creating meaningful connections with the community. Many of our team members dedicate their time and skills to causes close… August 10, 2023

-

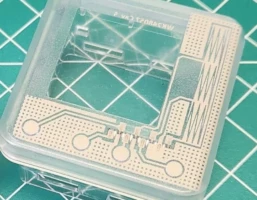

What Are In-Mold Structural Electronics (IMSE®)?

In-mold structural electronics (IMSE®) are a low-cost alternative to traditional designs and technologies, requiring fewer raw materials and zero assembly while improving product durability and the user experience. But despite these advantages, many manufacturers and molders are unfamiliar with the specifics of IMSE constructions. Sometimes referred to as in-mold electronics (IME), IMSE products combine durable graphics… June 20, 2023

-

The Benefits of In-Mold Structural Electronics (IMSE®) Compared to Conventional Electronics

In-mold structural electronics (IMSE®) represent the perfect blend of form and function: combining the aesthetics of in-mold decorating (IMD) with functional electronics. In other words, IMSE® helps manufacturers create finished products that incorporate both design and functional elements in a single part. This type of construction can offer significant advantages over conventional electronics designs. But… June 20, 2023

-

What Injection Molders Need to Know about In-Mold Decorating (IMD)

In-mold decorating (IMD) is used across industries as a valuable way to create durable, aesthetically pleasing plastic parts for a wide range of applications. There are many ways injection molders can benefit from adding IMD to their list of services, including higher dollar value projects, access to higher value markets, a larger customer base and other strategic… June 9, 2023