Flexographic labels

DuraTech creates custom solutions for flexographic labels

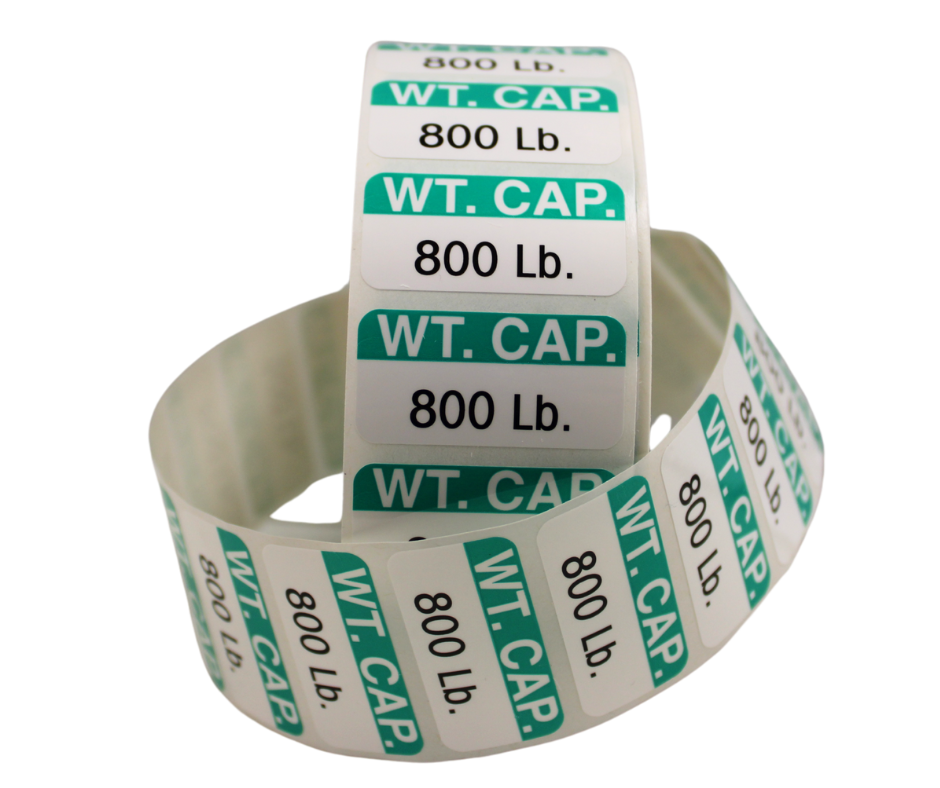

DuraTech offers flexographic printing services to create custom labels and other printing and identification solutions. This compatible printing alternative is designed to meet high-volume demands and is used in a variety of industries including the industrial, health and beauty, beverage and pharmaceutical markets. For applications that require a flexible, economic and high-quality process, industrial manufacturers should consider the total cost advantages related to flexographic printing’s one-pass printing, processing and finishing capabilities.

Download Our Information Guide & Capability Overview!

Our flexographic printing capabilities

Flexographic labels and other products printed with this technique can be formatted to match production application requirements whether it is roll, sheet, strip, individual or pin fed. We offer a wide array of colors, materials and finishes to customize products and extend the flexibility of this process. Flexographic printing is a viable choice for roll labels, tags, consecutive numbered barcodes and thermal transfer labels. Our die-cutting and slitting capabilities allow us to create the exact shape and size you need with tight tolerances. We can add an overlaminate to increase the durability of the printed label, and UL- and CSA-approved constructions are also available. We can also convert some screen-printed labels to flexographic labels.

Our flexographic printing capabilities include:

- 4-color printing process

- Barcodes and serialization

- UL/CSA-approved constructions

- Water-based inks

- UV inks for durable outdoor applications

- Gloss and matte UV coatings

- Thermal transfer coatings

- Die-cutting services

- Folding and fan folding

- Punching and drilling

- Eyelets and buttons

The benefits of flexographic labels

Flexographic labels can be less durable than digital or screen-printing products. However, they offer a number of other advantages. First and foremost, these labels are generally more economical and are better suited for consumable applications. Flexographic printing is also ideal for high-volume projects because it uses a roll to-roll process compared to other sheet-fed printing processes. Flexographic labels are a good choice for four-color processes and can accommodate spot colors as well. These products are also ideally suited for variable data printing such as barcodes and sequential numbering. If you’re looking to create economic labels that are well-suited for high volume production while providing complete customization options, flexographic labels may be the answer.