-

DuraTech’s IME: Dependability Through 4 Quality Tests

“Just how robust is your IME process?”We hear this question with increasing frequency. It’s a valid query. In-mold electronics (IME) technology is growing rapidly due to the attributes it offers engineers in designing 3D, smooth, decorative and easily cleaned surfaces with integrated capacitive touch, lighting, haptic feedback and antennas. IME also offers advantages in the reduction of… May 21, 2024

-

Enhance Your Home with Capacitive Touch Technology

What is capacitive touch?Capacitive touch, commonly known as cap touch, is a feature of in-mold structural electronics (IMSE) that is used in touchscreens and other touch-sensitive surfaces. At its core, capacitive touch relies on the electrical properties of the human body to detect and respond to a user’s touch. This technology is gaining immense popularity, particularly among… March 7, 2024

-

What You Need to Make Your Smart Products Attract Attention

In the ever-evolving environment of technology and innovation, those in the functional electronics industry are confronted with the need to not only keep pace but to stand out among competition. As we dive into the world of in-mold structural electronics (IMSE®), also referred to as in-mold electronics (IME), it is clear that improving the customer experience… February 20, 2024

-

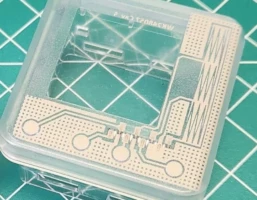

What Are In-Mold Structural Electronics (IMSE®)?

In-mold structural electronics (IMSE®) are a low-cost alternative to traditional designs and technologies, requiring fewer raw materials and zero assembly while improving product durability and the user experience. But despite these advantages, many manufacturers and molders are unfamiliar with the specifics of IMSE constructions. Sometimes referred to as in-mold electronics (IME), IMSE products combine durable graphics… June 20, 2023

-

The Benefits of In-Mold Structural Electronics (IMSE®) Compared to Conventional Electronics

In-mold structural electronics (IMSE®) represent the perfect blend of form and function: combining the aesthetics of in-mold decorating (IMD) with functional electronics. In other words, IMSE® helps manufacturers create finished products that incorporate both design and functional elements in a single part. This type of construction can offer significant advantages over conventional electronics designs. But… June 20, 2023

-

What Injection Molders Need to Know about In-Mold Decorating (IMD)

In-mold decorating (IMD) is used across industries as a valuable way to create durable, aesthetically pleasing plastic parts for a wide range of applications. There are many ways injection molders can benefit from adding IMD to their list of services, including higher dollar value projects, access to higher value markets, a larger customer base and other strategic… June 9, 2023

-

Why Proper Gating is Crucial to In-Mold Decorating (IMD) Success

In-mold decorating (IMD) gives manufacturers across industries an alternative process for creating more durable plastic parts. With IMD, graphics are printed on a film which is then inserted into a mold cavity. That cavity is then filled with resin to create a single finished part. But it’s how the resin actually gets into the mold —… June 9, 2023

-

The Future is Here With In-Mold Electronics

Imagine creating products that offer consumers increased simplicity, enhanced performance and jaw-dropping beauty – and doing so with cheaper production costs and less waste – making it more environmentally friendly. Not possible, you say? Think again. Think: “In-mold electronics (IME),” a promising technology that has numerous industries beginning to sit up and take notice. While… May 12, 2020

-

Your Guide to Choosing the Right In-Mold Decorator

In-mold decorating (IMD) – or in-mold labeling (IML) as it’s sometimes called – has been around for decades as a way to enhance product aesthetics and functionality, as well as solidify brand identities in the minds of consumers. However, IMD suppliers are not all created equally. And because IMD can be an involved, complicated process,… April 9, 2020