Die Cutting: Single, Kiss, and Crease Cuts Explained

An introduction to die cutting

In the world of custom printing and product enhancement, precision isn’t just important, it’s essential. At DuraTech Industries, our die cutting capabilities help shape high-quality components that meet your exact specifications. To do this effectively, we rely on three primary cutting methods: single, kiss, and crease cuts. Each technique plays a unique role in how your final product performs, looks, and functions.

Die cutting types

Die cutting is a versatile process, and at DuraTech, we utilize three primary types of cuts to meet the specific demands of each application. Each cutting method serves a distinct purpose and is selected based on the end-use requirements of the product. This range of capabilities allows us to deliver optimal results. Whether the goal is precise shape definition, easy peel functionality, or foldability for forming.

Our ability to execute these cuts with accuracy and consistency ensures that every finished component meets the highest standards of quality. To explore these cut types in more detail, watch our Types of Cuts video here.

Single cut

A single cut is used when a shape needs to be fully punched out from the material—whether that shape is a circle, square, or something entirely custom. This cut creates individual components that are cleanly separated and precisely formed, meeting exact dimensional specifications. It’s an essential method for producing finished parts that are ready for immediate use or further assembly.

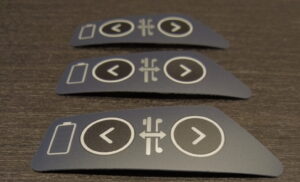

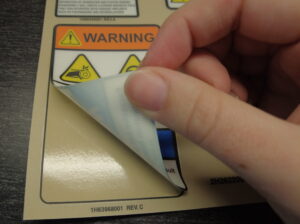

Kiss cut

A kiss cut is a precision technique where only the top layer of material, such as a label or adhesive, is cut, while the backing liner remains intact. This method is commonly used in applications like stickers or decals, allowing the finished product to be easily peeled from the liner without affecting the shape or integrity of the die cut. Kiss cutting is ideal for creating individual pieces or organized sets while maintaining clean presentation and ease of use.

Crease cut

A crease cut is formed by applying a blunt edge to the material, compressing it without fully cutting through. This creates a defined fold line that appears slightly thinner and more flexible than the surrounding areas. Crease cuts are particularly useful for parts that require bending or folding during assembly or final application, providing a clean, controlled way to shape the material without compromising its integrity.

What does this mean for you?

At DuraTech Industries, our commitment to quality extends to every stage of production, including die cutting. Understanding the differences between these cut types means you can make more informed decisions about how your product is produced. Whether you need a clean punch-out, a removable label, or a foldable element, DuraTech ensures the right cut is selected for the highest level of performance and visual appeal.

Are you ready to take your product to the next level with expert die cutting?

Get started today by requesting a quote. Let’s bring your vision to life!