What is the Difference Between a Set, Kit, and Combo?

When managing complex label requirements, finding efficiencies in both cost and logistics is essential. At DuraTech Industries, we offer smart solutions to help customers reduce expenses and simplify processes, especially when multiple parts are involved.

Depending on your specifications, we may recommend printing your labels as a set, kit, or combo; each of these options is designed to reduce setup costs and improve the ordering process.

But what exactly is the difference between these three options, and how do you know which is right for your project? Below, we break down the unique advantages of sets, kits, and combos to help you determine the best fit for your application.

What is a set?

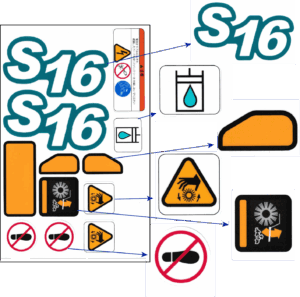

A set refers to a group of parts that share a single part number, are produced at the same time, and are packaged and shipped together. All components within a set must be made from the same material so they can be supplied either as one continuous sheet or as individually cut pieces bundled together.

Sets are ideal when multiple labels or overlays will be applied to the same end product, such as different decals used on a single machine. For added convenience, we can print part numbers or placement instructions in the scrap areas, helping to streamline application on the production floor.

It’s important to note that set configurations are fixed. If design or layout changes are needed after a set is tooled, additional setup costs may apply.

What is a kit?

A kit is a group of related parts ordered under one part number but produced separately, each on its own work order, before being packaged or shipped together. Kits are commonly used when the individual components require different materials or manufacturing processes.

Like sets, kits are ideal for grouping parts that will be used on the same piece of equipment or product. Since each item in a kit is manufactured independently, they simplify ordering, stocking, and part management by consolidating everything under a single part number.

This makes kits a practical choice for projects that require variety without sacrificing organization or convenience.

What is a combo?

A combo is a group of parts, each with its own unique part number that are produced together on the same material and then packaged and shipped individually. To qualify as a combo, all parts must be compatible in terms of material type and should share similar color schemes to ensure efficient production.

Combos offer a cost-effective option by reducing setup times and streamlining production runs. By combining multiple part numbers into a single manufacturing batch, customers can gain efficiency without compromising on part differentiation.

However, it’s important to note that combo pricing is based on a specific grouping of part numbers. Any adjustment to the part quantities may result in change to individual unit prices and additional set up charges may apply.

Working with DuraTech

Whether you choose a set, kit, or combo, bundling your printed parts offers distinct advantages. At DuraTech, we provide flexible options for multi-part printing that support your goals, whether that’s simplifying reorders, reducing costs, or ensuring a consistent look across your products. Our goal is to make your ordering process easier, so you can focus more on what matters most.

We hope this guide has offered helpful insight into the bundling solutions available at DuraTech Industries. For more information about the materials we offer for sets, kits, or combos, check out our Ebook on label and overlay materials here.

Are you ready to take the next step with us?

Click the link below to request a quote from our team. We would be happy to speak to you!